|

|

| |

|

|

|

| |

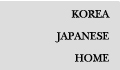

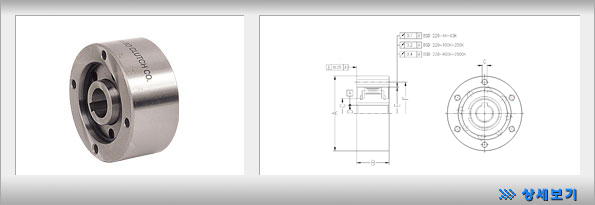

Specification

Specification |

Dimensions-mm |

|

|

| Model |

Max.

Torque

(kgf-m) |

Max.

Overrunning

(rpm) |

Stock Bore Size |

A |

C |

E |

F |

B |

G |

H |

I |

L |

No. of

Holes

(N-M) |

Oil

(cm©ø) |

Weight

(kgf) |

| BSD 260 |

Standard

bore |

Max.

bore |

| -4K |

26 |

3,800 |

16 |

16 |

67 |

25 |

47 |

56 |

34 |

10 |

19 |

1.0 |

53 |

4-M5 |

10 |

1.1 |

| -6.3K |

54 |

2,550 |

20 |

20 |

80 |

30 |

55 |

68 |

38 |

11 |

24 |

1.0 |

62 |

4-M5 |

12 |

1.5 |

| -10K |

90 |

2,400 |

25 |

25 |

95 |

40 |

68 |

82 |

42 |

12 |

31 |

1.0 |

73 |

6-M5 |

17 |

2.2 |

| -16K |

100 |

2,200 |

28 |

30 |

105 |

45 |

75 |

90 |

42 |

12 |

32 |

1.0 |

74 |

6-M6 |

22 |

3.1 |

| -25K |

220 |

2,000 |

35 |

40 |

125 |

55 |

90 |

107 |

52 |

12 |

33 |

1.0 |

85 |

6-M6 |

35 |

4.2 |

| -40K |

240 |

1,750 |

40 |

45 |

135 |

60 |

95 |

115 |

52 |

14 |

37 |

1.0 |

89 |

6-M8 |

45 |

5.4 |

| -63K |

340 |

1,450 |

45 |

50 |

150 |

70 |

110 |

130 |

60 |

16 |

42 |

1.0 |

102 |

6-M10 |

65 |

7.4 |

| -100K |

640 |

1,200 |

55 |

60 |

180 |

85 |

130 |

155 |

74 |

22 |

50 |

1.0 |

124 |

6-M10 |

125 |

13.1 |

| -160K |

880 |

1,000 |

70 |

75 |

210 |

100 |

150 |

180 |

76 |

26 |

54 |

1.0 |

130 |

6-M12 |

170 |

18.0 |

| -250K |

1,520 |

850 |

80 |

90 |

245 |

120 |

180 |

214 |

85 |

28 |

65 |

1.0 |

150 |

8-M12 |

290 |

30.0 |

| -400K |

2,160 |

720 |

95 |

100 |

280 |

140 |

210 |

245 |

100 |

29 |

71 |

1.5 |

171 |

8-M16 |

440 |

44.0 |

| -630K |

3,720 |

650 |

110 |

130 |

320 |

160 |

240 |

280 |

115 |

33 |

90 |

1.5 |

205 |

8-M20 |

610 |

74.0 |

| -1000K |

6,400 |

560 |

130 |

140 |

370 |

180 |

280 |

325 |

140 |

38 |

94 |

1.5 |

234 |

8-M20 |

780 |

117.0 |

| -1600K |

9,200 |

480 |

140 |

150 |

410 |

200 |

310 |

360 |

160 |

38 |

108 |

2.0 |

268 |

8-M24 |

850 |

167.0 |

| -2500K |

13,000 |

400 |

160 |

160 |

460 |

220 |

340 |

400 |

180 |

45 |

109 |

2.0 |

289 |

8-M30 |

1,300 |

250.0 |

|

| |

Character Character |

|

| 1. Oil Lubrication |

| 2. BSD 260-K Series can be used for overrunning with gea rreducer. |

| 3. Please use standard bore. |

| 4. The key way is in accordance with DIN 6885 sheet 1. |

| |

|

| |

|

| |

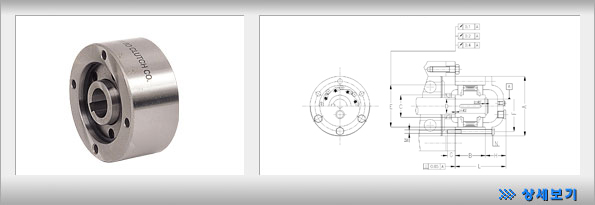

Specification

Specification |

Dimensions-mm |

|

|

| Model |

Max Torque

(kgf-m) |

Max.

Overrunning

(rpm) |

Stock

Bore Size |

A |

C |

E |

F |

B |

No. of Holes

(N-G) |

Weight

(kgf) |

| BSD 220 |

Inner

Race |

Outer

Race |

Stamdard

bore |

Max.

bore |

| -4K |

26 |

3,800 |

7,000 |

16 |

16 |

67 |

25 |

47 |

56 |

34 |

4-¨ª5.5 |

0.8 |

| -6.3K |

54 |

2,400 |

4,800 |

20 |

20 |

80 |

30 |

55 |

68 |

38 |

4-¨ª5.5 |

1.1 |

| -10K |

90 |

1,700 |

3,500 |

25 |

25 |

95 |

40 |

68 |

82 |

42 |

6-¨ª5.5 |

1.6 |

| -16K |

100 |

1,400 |

3,000 |

28 |

30 |

105 |

45 |

75 |

90 |

42 |

6-¨ª6.6 |

2.6 |

| -25K |

220 |

1,250 |

2,500 |

35 |

40 |

125 |

55 |

90 |

107 |

52 |

6-¨ª6.6 |

3.4 |

| -40K |

240 |

1,100 |

2,000 |

40 |

45 |

135 |

60 |

95 |

115 |

52 |

6-¨ª9 |

4.0 |

| -63K |

340 |

960 |

1,700 |

45 |

50 |

150 |

70 |

110 |

130 |

60 |

6-¨ª11 |

5.6 |

| -100K |

640 |

840 |

1,500 |

55 |

60 |

180 |

85 |

130 |

155 |

74 |

6-¨ª11 |

11.0 |

| -160K |

880 |

745 |

1,300 |

70 |

75 |

210 |

100 |

150 |

180 |

76 |

6-¨ª14 |

14.0 |

| -250K |

1,520 |

635 |

1,150 |

80 |

90 |

245 |

120 |

180 |

214 |

85 |

8-¨ª14 |

25.0 |

| -400K |

2,160 |

550 |

1,000 |

95 |

100 |

280 |

140 |

210 |

245 |

100 |

8-¨ª18 |

35.0 |

| -630K |

3,720 |

480 |

900 |

110 |

130 |

320 |

160 |

240 |

280 |

115 |

8-¨ª22 |

55.0 |

| -1000K |

6,400 |

420 |

800 |

130 |

140 |

370 |

180 |

280 |

325 |

140 |

8-¨ª22 |

83.0 |

| -1600K |

9,200 |

360 |

700 |

140 |

150 |

410 |

200 |

310 |

360 |

160 |

8-¨ª26 |

121.0 |

| -2500K |

13,000 |

320 |

650 |

160 |

160 |

460 |

220 |

340 |

400 |

180 |

8-¨ª33 |

180.0 |

| -4000K |

22,200 |

150 |

200 |

210 |

210 |

560 |

300 |

440 |

500 |

180 |

12-¨ª33 |

265.0 |

| -6300K |

37,000 |

100 |

150 |

230 |

230 |

680 |

330 |

520 |

605 |

230 |

16-¨ª33 |

395.0 |

|

| |

Character Character |

|

| 1. Oil lubrication |

| 2. BSD 220-KSeries can be used for overrunning in a gear reducer. |

| 3. Please use standard bore. |

| 4. The key way is in accordance with DIN 6885 Sheet 1. |

| |

|

| |

|

|